It started out with cable ties, a battery dewalt router and bread boards. It's now a fully scaled water cooled spindle with commercial 32bit controller.

Our first project was to create 12mm H3.2 ply fence panels as I was in the trellis business. It didn't take long to understand ply was not a very durable product to work with. I went though a few products until I came across ACM. It was harder to cut and work with the results were fantastic. Stong, flat and lightweight products that didn't rust. The problem was it was white. I experimented with painting the ACM, but found the finish to be average. I wanted a quality long lasting finish that can be outside in direct sunlight and weather.

After a lot of research I found a quality New Zealand distributor of coloured ACM. After testing by scrubbing, water blasting and leaving out in direct sunlight over summer with no fade I found the ACM required.

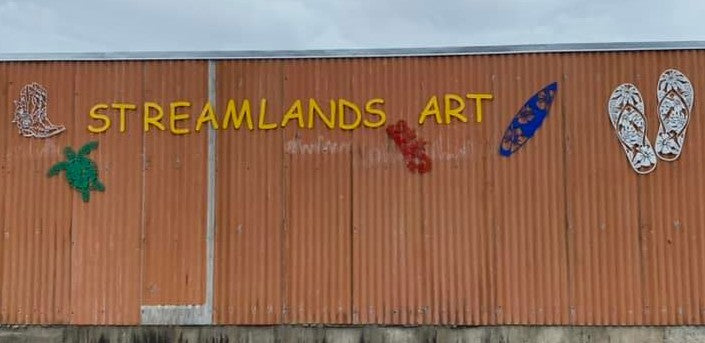

Th colors are limited as we only source commercial graded colors that are used in the building industry. Getting the colours over the last 12 months has been a challenge, so we decided to build our own warehouse and bulk buy in the sheets. This insured we have a supply and saved on cost with bulk buying.